Vietnam’s open-pit coal mines have been and will continue to play an important role in the development of Vietnam’s coal industry. In order to ensure the safety of deep mining, meet the output requirements, and improve the efficiency of mining, it is necessary and urgent to research appropriate technological solutions.

Developing principles for selecting mining technology

Within the framework of the National Key Science and Technology Program to serve the renewal and modernization of mining and mineral processing technologies by 2025, the Ministry of Industry and Trade has assigned the Institute of Mining Science and Technology – Vinacomin. implementing the Project “Research on appropriate technological solutions when exploiting deep layers in open-pit coal mines in Vietnam”

|

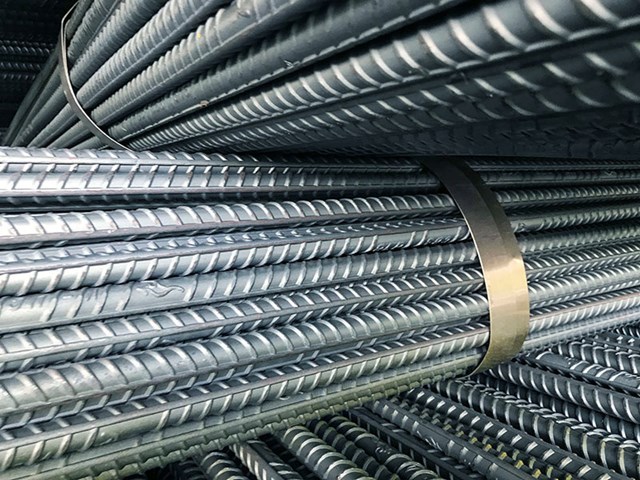

In the coming years, Vietnam’s opencast coal mines will increase their exploitation intensity

The topic has completed the research contents: An overview of mining experience at deep layers in the world, assessment of the current state of mining technology and equipment at deep open pit coal mines in Vietnam; study the geotechnical factors affecting technologies when mining in deep mining strata of opencast coal mines in Vietnam; research and propose technological solutions suitable to the conditions and effectively exploit in the deep layers of Vietnam’s open-pit coal mines; pilot application of one of the mining technology solutions at a deep open pit coal mine in Cam Pha area.

Dr. Do Ngoc Tuoc – Project manager said: The project has assessed and synthesized characteristics of technical and geological conditions; assessment of the current state of technology in drilling and blasting equipment, loading and unloading – transportation, dumping, drainage, dredging, deep excavation, solutions to improve safety and mining plans in the coming time. Simultaneously, overview of experience in deep underground mining in countries around the world, forecast geotechnical conditions in deep layers.

From there, develop principles of mining technology selection and use of mine modeling, technological stages and change the input data according to the forecast of technical conditions of the mine when deep mining to select options. and technical specifications.

Through the economic technical evaluation, the options will be selected with the optimal scheme and technological parameters such as: Mine bank: Applying convex mining technology combined with solutions to improve the stability of the mine bank, select and arrange suitable equipment on the working zone; Exploiting technology: Applying drilling and blasting technology to increase the slope angle of the floor, reduce vibrations, load explosives in plastic bags, charge and explode bulk emulsions by special vehicles…

For dredging: Apply dredging technology with a solid mud pump for the upper part of the thin mud, the rock and mud below are directly exposed by hydraulic excavators with reverse bucket; transport technology: applying the combined technology of automobile – slope conveyor – conveyor belt usually combined with crusher or automobile transport technology – load shaft, conventional car transport technology – crawler automobile.

Regarding the preparation of new layers and deepening: Dig deep into the bottom of the inclined, multi-level, stratified mine in accordance with the specifications of the hydraulic excavator and ensure the required output; technology of dumping waste at the landfill below with underground mining: The technology of dumping waste according to the circumference, the order of dumping from the bottom up, with a height of the waste layer from 20-30 m. In each floor, the dumping work is carried out in layers with the height of each layer from 5-10m. The width of the waste layer is 10-20m (dry season) and 15-25m (rainy season).

In particular, when the mine goes deep, the climatic conditions become more and more complicated. At that time, natural ventilation will not be enough to disperse all harmful gases and dust concentrated in the deep part of the mine, it is necessary to apply mixed ventilation, combining natural ventilation with artificial ventilation to enhance mine ventilation, creating a fresh atmosphere and a clean and safe working space for workers.

The solution of the topic is highly feasible

According to Dr. Do Ngoc Tuoc: Currently and in the coming years, Vietnam’s open-pit mines will increase their exploitation intensity. The deeper you go, the more difficult it is to exploit. Therefore, it is necessary to research and apply appropriate mining technology solutions at deep layers. “Optimal technological parameters and scientific and practical proposed technological processes can be used for deep layers” – Dr. Do Ngoc Tuoc emphasized.

However, water sludge treatment technology requires investment in mud pump equipment and short sludge treatment time to ensure deep excavation requirements. The technology of dumping waste in layers needs to be monitored for a long time, with evaluation data from surface monitoring works, water in the furnace… Meanwhile, drilling and blasting in deep layers due to large groundwater levels Therefore, the cost of drilling and blasting increases, this is one of the big problems that need to be solved.

In the world, deep open pit mines apply solutions such as: Using mining equipment with large capacity, applying technology to break rock by advanced methods, applying mining of convex mines. , using combined transport equipment (cars – slope conveyors – normal conveyors, crawler cars – load shafts, crawler cars – normal cars), exploiting with large floors.

“Thanks to the application of technical advances, many open-pit mines have expanded their mining scale. The principles of structural calculation, mine bank stability, drilling and blasting technology, equipment synchronization, mine ventilation, etc., can be used in deep mining floors in open-pit coal mines in Vietnam. – Dr. Do Ngoc Tuoc said.

Vietnam’s open-pit coal mines have the form on the mountainside under the deep pit, the depth of exploitation is large. Hydrogeological conditions – the work is very complicated, the deeper the mining conditions, the more difficult it is. The coal seams have a complex structure, many folds and faults; The stratigraphy of the areas on the mine shore is not uniform. Currently, the mines are in the process of deep mining.

T&G International Joint Stock Company

Address: 352 Hue Street, Le Dai Hanh Ward, Hai Ba Trung District, Hanoi

Hotline: 0345786803

Email: hrm@tginterjsc.com

Website: http://tginternationaljsc.com