Each car ‘born’ requires 900 kg of steel, how is the auto industry affected when steel prices rise?

Steel is an important material in the automotive industry. Manufacturers need an average of 900 kg of steel to produce a car. Steel is used to make frames, bodies, machines, door panels, silencers, exhaust pipes…

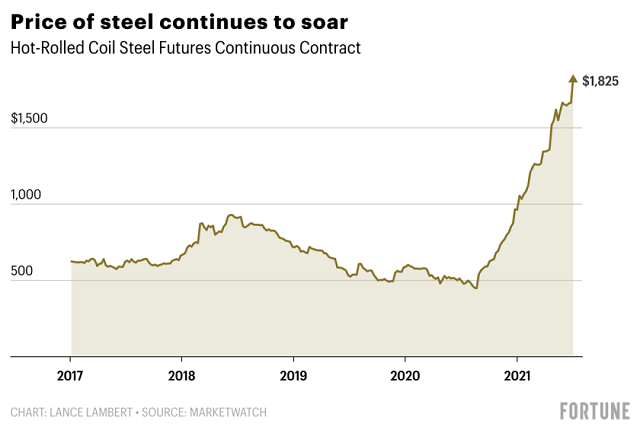

According to Fortune, since March 2020, steel prices have increased by 215%. The price of hot rolled coil (HRC) which is the most used steel in the industry rose to an all-time high in the last week of June and early July, reaching $1,825 per ton. Before the pandemic, the price of this material was only about 500-800 USD/ton.

Steel prices rose due to increased world demand, higher iron ore prices, and the tightening of iron production in China. The increase of important materials in automobile production will affect this industry.

In India, steel prices increased from October 2020 and adjusted in February this year. However, then the price of this item continued to increase in March and April. Here, the auto industry accounted for 9% of steel consumption, behind construction and real estate with 55-60%.

Manufacturers offset input costs by increasing vehicle prices

“Most of the world’s leading auto manufacturers raised prices for the second time with an increase of about 1-3% in April, after having increased by 3-4% this year, to offset the impact of high steel prices. more,” said Motilal Oswal Institutional Equities, an Indian brokerage and finance group, on The Hindu Business Line.

According to a senior official at Honda, a Japanese car and motorcycle manufacturer, Honda plans to raise the prices of all models in India from August to offset the impact of increased input costs due to high prices. steel and precious metals go up. The company is working on specific increases.

Rajesh Goel, Senior Vice President, Honda Cars India said: “Price of raw materials such as steel, aluminum and precious metals increased sharply. Many materials increased at a record rate, greatly impacting the input costs of production. Mr. Goel also revealed that the company is calculating a specific increase to apply in August.

“Our effort is to keep purchasing costs lower. So we consider how much we can afford and will inevitably increase product prices. Price adjustments will be made in the coming weeks. next month,” Mr. Goel said.

With input costs rising, Maruti Suzuki India (MSI) in June announced a price increase of its entire product portfolio in the fourth quarter. Previously, the company also increased the price of some products.

According to Bloomberg journalist Anjani Trivedi, the increase in input materials causes manufacturers to reduce incentives and discounts for customers. In fact, it’s already happening in the world’s biggest auto markets, the US and China.

However, companies have few options to offset the escalating production costs. When prices rise, consumers will no longer spend comfortably. The US vehicle affordability index has dropped. That shows that many people start to hesitate when buying a car. Nearly 40% of customers who intend to buy a car have abandoned the idea.

T&G International Joint Stock Company

Address: 352 Hue Street, Le Dai Hanh Ward, Hai Ba Trung District, Hanoi

Hotline: 0345786803

Email: hrm@tginterjsc.com

Website: http://tginternationaljsc.com