China’s huge manufacturing industry is being hit hard by power shortages. From steel and cement factories to dyeing factories, they are having to reduce capacity or temporarily suspend operations under the country’s order to limit electricity consumption.

Industries with controlled electricity consumption

According to Reuters, from home appliance manufacturers to car companies, construction and solar panel manufacturers could face production cuts as China plunges into a power shortage crisis.

Controlling metal output to target carbon emissions in the winter is nothing new for China’s steel and aluminum producers.

However, the high demand for electricity, but the scarce supply of coal, caused the country to fall into a power shortage during the summer, many large power-consuming plants had to stop working. Everyone is worried about not having enough electricity to keep warm when winter is approaching.

Enterprises in fields such as aluminum and cement production are being classified as large power consuming industries, forced to limit production to give priority to industries that consume less electricity.

Fertilizer manufacturers are also notorious “electric vacuums”, affected by power cuts and rising electricity prices. However, this industry has an important role to play, ensuring national food security should be allowed to maintain operations and ensure electricity supply.

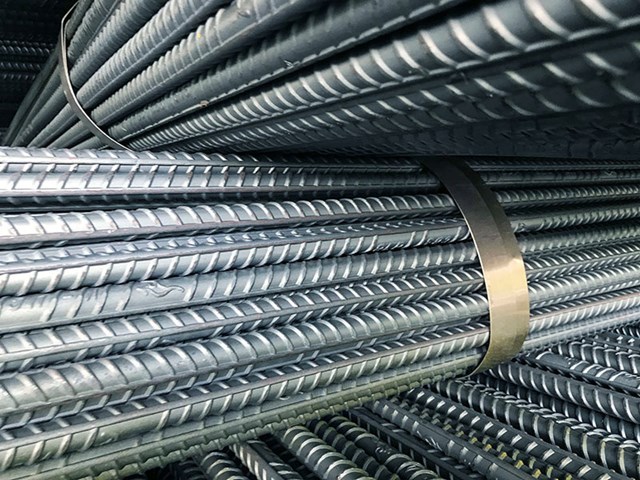

The metal industry is the hardest hit

Many metal manufacturers received orders to reduce work throughout to save energy, resulting in a shortage of important industrial raw materials.

Much of China’s metal production is concentrated in supply-tight regions such as Jiangsu, Hebei, Xinjiang and Yunnan because electricity demand exceeds supply and forces the government to take action. drastic action to try to prevent excessive electricity consumption.

For cement, 35% of China’s total production has been affected and about 30-40% of petrochemical production capacity is also in this situation.

China will produce about 1.5 million tons less aluminum than planned this year, meaning a loss of 4 percent in metal revenue, said Colin Hamilton, market analyst at BMO Capital Markets. 5 billion USD.

Prices of many commodities are trending up hot, such as steelmaking materials such as ferrosilicon and silicomanganese, respectively, up 87% and 58% in the third quarter because of regulations restricting electricity consumption.

Similarly, China’s coal and metal prices soar amid a power crisis, forcing production cuts

.

“We anticipate that electricity supply will be quite scarce during the winter,” said Ms. Hanna.

The aluminum industry’s need to limit electricity consumption also originated in Inner Mongolia and spread to the Yunnan region in southwestern China.

Over the past three years, aluminum smelters have moved to the province one after another, becoming a center for tin and zinc production and benefiting from the exploitation of the often abundant hydroelectricity. However, severe drought conditions put pressure on the power supply system, peaking in May and June.

Mr. Paul Adkins, CEO of market consulting firm AZ China, said that Chinese aluminum companies also try to change to comply with carbon emission regulations, but the problem is that there is not enough energy. renewable to meet 20% of demand.

Production costs skyrocketed

Smelters also have to spend large sums of money buying raw materials to maintain thermal power plants as China’s thermal coal futures prices near record highs above 1,300 yuan ($200) a tonne. .

Not only key industries, dye factories, soybean grinding mills are also required to reduce capacity or suspend operations to reduce electricity consumption, at least until the end of the National Day holiday. China 1/10, maybe even longer.

“China’s power shortage is a reflection of global stress in energy markets and will not be resolved overnight,” Capital Economics said.

The capacity allocation will limit industrial activity until demand weakens enough to bring the domestic electricity market back to equilibrium.

A prolonged metal outage risks putting end-users at risk, who are already faced with soaring commodity prices.

“The key concerns for the auto supply chain are the costs of pushing up inflation and tightening upstream supply which could impact downstream production/profits,” Morgan Stanley said.

Address: 352 Hue Street, Le Dai Hanh Ward, Hai Ba Trung District, Hanoi

Hotline: 0345786803

Email: hrm@tginterjsc.com

Website: http://tginternationaljsc.com