Output restrictions tied to winter emissions limits are nothing new for China’s steel and aluminum producers. However, many metal producers were ordered to cut operations to conserve energy throughout the summer, resulting in a drop in output of the key industrial raw material.

Metals consumers in China, from manufacturers to companies, to construction… are poised to face potential supply shocks after power cuts and power shortages forced some Metallurgical plants have had to cut output in recent weeks.

Output restrictions tied to winter emissions limits are nothing new for China’s steel and aluminum producers. This year, however, power constraints persisted throughout the summer due to low coal supplies and strong demand, leading to forced closures of energy-intensive operations and worries about insufficient heating. when cold weather approaches.

Power consumption sectors such as aluminum and cement also consistently ranked first as regions of China were required to double efforts earlier this year to meet targets, energy consumption and lower intensity.

|

Fertilizer producers, too, have been affected by power cuts and rising costs, but because of their importance to food security, they have been allowed to maintain high operating speeds and are guaranteed. secure power supply.

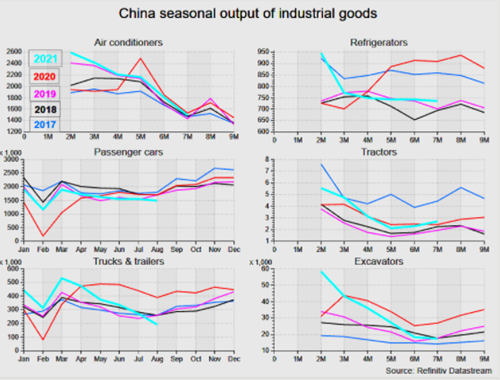

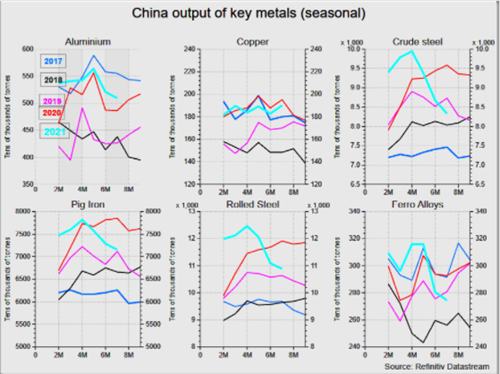

PRODUCT OF IMPORTANT INDUSTRIAL MATERIALS DECREASE

However, many metal producers have been ordered to cut operations to save energy, resulting in reduced output of the key industrial raw material.

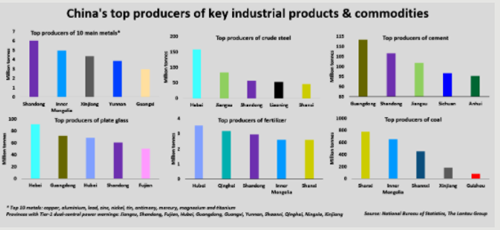

Much of China’s metal production is concentrated in severely power-constrained regions, including Jiangsu, Hebei, Xinjiang and Yunnan, as soaring electricity demand outstrips supply and forces the government to must take drastic action to try to prevent the loss.

China stopped manufacturing key industrial products and commodities.

Investment bank Morgan Stanley estimates 7% of aluminum capacity in China has so far been affected by the power cuts, while around 67% of China’s total steel capacity across 11 provinces have announced some measure. output control measures for the second half of 2021.

For cement, 35% of total production and about 30%-40% of China’s main petrochemical production capacity have been affected.

China will produce 1.5 million tonnes less aluminum than planned this year, meaning a loss of metal revenue of $4.5 billion, said BMO Capital Markets analyst Colin Hamilton.

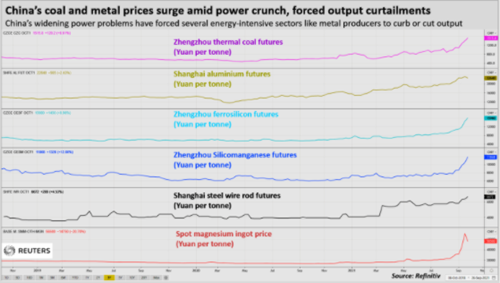

Some of the biggest commodity price gains this year have been in steelmaking raw materials such as ferrosilicon and silicomanganese, which rose 87% and 58% respectively this quarter, as limited energy forced output cuts.

|

China’s coal and metals prices soar amid an energy downturn, forcing output cuts.

Clare Hanna, senior steel analyst at CRU estimates China’s silicomanganese production fell 40% in July 2021 compared to June 2021 as restrictions that started in Inner Mongolia spread to Guangxi and a number of other places.

“We anticipate that electricity will be quite scarce during the winter,” Hanna said.

Production restrictions on aluminum also began in Inner Mongolia before spreading to Yunnan in the southwest of China. Over the past three years, aluminum smelters have shifted capacity to the provinces of Yunnan, also a major tin and zinc hub, to tap China’s abundant hydroelectric power, but severe drought in October. May and June of this year also had serious effects.

|

China’s Key Metals

According to Paul Adkins, managing director of consulting firm AZ China, Chinese aluminum companies have sought to catch up with the low-carbon aluminum trend.

But “there is simply not enough renewable energy to support more than 20% of total demand”

BOOKED COSTS

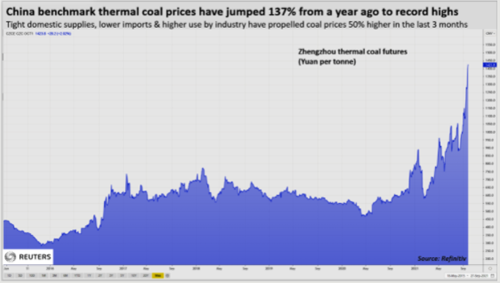

Smelters also face hefty costs to secure enough coal for power plants forced to cut, with China thermal coal futures near a record high above CNY 1,300 (equivalent to CNY 1,300). equivalent to 200 USD)/ton.

|

China’s thermal coal price increased by 137% compared to 2020

Dozens of manufacturers ranging from dye makers to soybean crushing plants have also had to cut back or shut down operations at least through the upcoming National Day holiday from October 1. , although some market observers think the restrictions will last longer.

China’s power shortages reflect the strain on energy markets globally and will not be resolved overnight, Capital Economics said.

“The capacity allocation will limit industrial activity until demand weakens enough to bring the domestic electricity market back to equilibrium.”

A prolonged shutdown of the metal risks putting some people forced to use the commodity later in the year, facing rising prices.

“The main concern for the auto supply chain is the cost of inflation and upstream supply tightening that could impact downstream production/profits,” said Morgan Stanley.