Power shortages in China have forced factories to cut output, posing new risks to the global supply chain, which has already been plagued by difficulties due to the impact of the COVID-19 epidemic. In Vietnam, the market that imports many input materials from China, how will it be affected by this situation?

Power shortage in China causes production to shrink

According to Bloomberg, China, the world’s largest exporter, is forced to save energy by cutting production.

The disruption comes at a time when manufacturers and carriers are racing to meet demand for the year-end shopping season. At the same time, the world supply chain has been disturbed by skyrocketing raw material prices, prolonged delays at seaports, and shortages of shipping cointainers.

Chinese manufacturers warn that severe measures to cut electricity consumption will sharply reduce output in economic hubs such as Jiangsu, Zhejiang and Guangdong and could drive prices up. These three provinces account for nearly a third of China’s GDP.

Local governments are ordering power cuts to try to meet targets to cut energy intensity and emissions. Some are actually facing power shortages.

Many manufacturing plants in China are in trouble with energy shortages. (Photo: CNN).

According to CNBC, a survey of the National Bureau of Statistics of China (NBS) released on September 30 showed that the purchasing management index (PMI) in September was 49.6, down from 50, 1 of August. According to the PMI scale, a point below 50 indicates a downturn in manufacturing activity.

This is the first time China has seen a contraction in manufacturing activity after 18 months of continuous growth, since February 2020. NBS attributed the slowdown to the weakening of factories due to rising energy costs.

In fact, electricity shortages in China occur due to many reasons. One of them is because China stopped importing coal from Australia because of escalating geopolitical tensions. Meanwhile, a record cold winter has increased demand for coal. This caused the price of coal to increase sharply.

China is paying a heavy price for policies that limit domestic coal production and imports, and lead to a shortage of fuel that still supplies much of the world’s second-largest economy. Reuters reported.

To solve the problem, China will increase imports and boost domestic output in the coming months. However, China is having problems both from domestic and international supply.

In December 2020, China produced nearly 352 million tons and then gradually decreased. By July this year, output was just over 314 million tons, the lowest level since May 2019. By August, production reached 335.2 million tons, but still below the country’s potential.

Coal imports in the first 8 months of the year decreased by 10.3% over the same period in 2020, reaching only 197.7 million tons. In August alone, the import level was more than 28 million tons, down from 30.2 million tons in July.

Import volume is low, but coal prices have increased due to China’s policy of banning coal purchases from Australia, the second largest supplier of coal to China with about 60% used for power generation and industries such as cement. cement and about 40% of coke are used to make steel.

Last June, China imported 9.8 million tons from Australia but since January this year, the number has been almost zero.

To make up for the shortfall from Australia, China buys coal from Indonesia, Russia, South Africa and the US. However, coal prices have risen very high.

The price of Indonesian coal is also record high and China has to race with India to buy from Indonesia. Coal grade 4,200 kcal/kg in the week to September 24 was at $91.3/ton, four times higher than the low in 2020.

Will Vietnamese manufacturers be affected?

The energy crisis has dealt a blow to the world’s second economy, with the risk of disrupting the global supply chain, will it have an impact on neighboring markets like Vietnam?

Answering this question, at the press conference usually signed in September, Mr. Nguyen Ngoc Thanh, Deputy Director of the Department of Industry (Ministry of Industry and Trade), said that in fact, the price of some input materials for the power industry as well as China’s emission reduction has caused a shortage of electricity, leading to a decrease in some industrial production, including raw materials for the market.

However, up to now, the Ministry of Industry and Trade has not recorded that domestic enterprises have reported a lack of input materials.

Mr. Nguyen Ngoc Thanh shared, in fact, many domestic enterprises have faced a shortage of raw materials since the first outbreak of the disease in 2020. The disruption of the supply of input materials from textiles and garments. , leather and footwear as well as products provided for heavy industry have also been responded and gradually adapted by experienced enterprises.

(Photo: financialtribune.com)

In addition, with the 3rd and 4th disease re-infection in the past time, the capacity of domestic industrial production enterprises has since been reduced, even some enterprises in 19 southern provinces. must stop working.

Therefore, the current demand for input materials has not been clearly seen and businesses have not mentioned this issue.

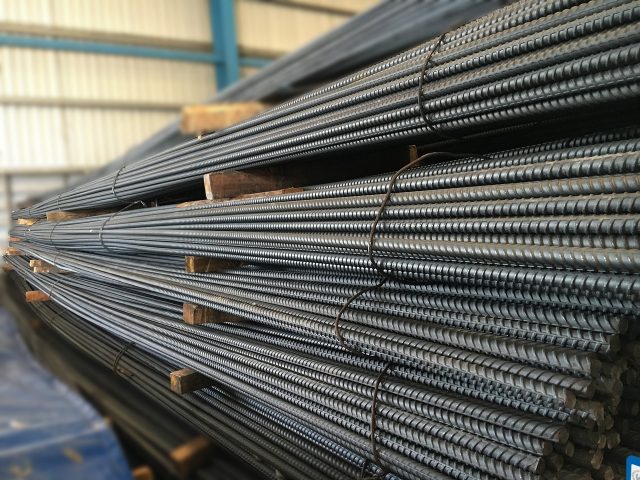

“In the long term, some products, such as domestic steel products, can be completely met, such as construction steel, we don’t worry about dependence on other countries. Some industries are different from other countries. short-term fluctuations like the recent from China, at this time, it is not possible to assess the great impact on Vietnam’s input materials,” said Deputy Director General Nguyen Ngoc Thanh.

However, sharing with the writer, Mr. Nguyen Quoc Anh, Chairman of the Ho Chi Minh City Rubber and Plastic Association, said that 80% of the raw materials of the rubber and plastic industry are imported from China. In the short term, the lack of electricity from China has not had a big impact on the domestic supply of raw materials since inventories are still available and orders placed 2-3 months in advance are still on their way to port with prices not increasing.

“But now, some suppliers have announced that they will increase prices by 5-10% compared to the old price for orders purchased from now until the end of the sixth quarter, so the situation of both shortage of raw materials and high prices is difficult to avoid.” , Mr. Quoc Anh said.

According to the HCM City Rubber and Plastic Association, with the increase in prices from Chinese suppliers, businesses are forced to accept because if they change the supply to markets like the US or Europe, the price will also be much higher.

“The source of raw materials from China has two advantages: the price is cheaper than other markets and goods from China to Vietnam are also closer and faster than countries like the US and Europe, so the sourcing Others have to find it, but it will be more difficult than accepting it from China,” said Mr. Nguyen Quoc Anh.

As for the textile industry, Mr. Vu Duc Giang, Chairman of the Vietnam Textile and Apparel Association (Vitas), said that China’s electricity shortage will more or less affect the input material supply of the textile industry, but rate is not much.

“With about 45% of raw materials imported from countries such as Japan, Taiwan, China, India… The lack of electricity in China will affect the raw material contracts that Vietnamese enterprises have signed. signed as well as delivery time at the rate of about 10-15% of input materials.

In addition, the source of imported raw materials for the production of orders in the previous months is still backlogged due to the impact of the COVID-19 pandemic, so in the last months of the year, the problem of raw materials is not too difficult for customers. textile industry,” said Mr. Giang.

T&G . International Joint Stock Company

Address: 352 Hue Street, Le Dai Hanh Ward, Hai Ba Trung District, Hanoi

Hotline: 0345786803

Email: hrm@tginterjsc.com

Website: http://tginternationaljsc.com